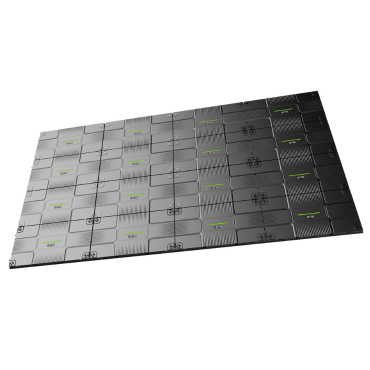

COB LED Screen Series

| Pixel Pitch | P0.6 P0.78 P0.93 P1.25 P1.56 |

|---|---|

| Cabinet size: | 600*337.5MM |

| Module size: | 150*168.75mm |

| Refresh rate: | 3840Hz |

| Power: | Max:600W/sqm,Avg:150W/sqm |

| Waterproof : | IP43 |

| Brightness: | 600 |

| Input Voltage: | AC90-264V |

COB LED VS SMD LED What Is The Difference Between LED and COB LED?

SMD LED and COB LED Definition?

Cob LEDs and SMD LEDs are both types of light-emitting diodes (LEDs), but there are some differences in terms of their physical characteristics, application, and manufacturing process.

Cob LEDs are made using a traditional method of growing gallium nitride crystals and then encapsulating them in a metal matrix. This process is more complex and expensive than the SMD process used for SMD LEDs. Cob LEDs also tend to be larger and heavier than SMD LEDs, which makes them less suitable for smaller electronic devices such as smartphones and wearables.

On the other hand, SMD LEDs are manufactured using a flip-chip process that involves attaching the LED chip to a plastic substrate. This process is simpler and more cost-effective than the traditional method of growing crystals, and it allows for the creation of smaller and more compact LEDs. SMD LEDs can be mounted directly onto printed circuit boards or other electronic components, making them highly versatile and useful for a wide range of applications.

In summary, cob LEDs offer better performance and higher quality, while SMD LEDs are more cost-effective and versatile.

COB LED Screen VS SMD LED

Production Process:

The COB LED Screen is to directly weld the LED chip to the PCB circuit board. SMD LED Screen is to make the LED chip into a patch-type LED lamp bead, and then the lamp bead is fixedly welded to the PCB board. There are more The production process of manufacturing LED lamp beads and patches. It can be seen that the COB process is single and the stability of the product is very high. The SMD LED Screen production process has more steps for LED lamp beads and patches. If there is a problem with the quality of the LED lamp beads and the patch and the film quality, the quality of the SMD LED Screen will also be greatly reduced.

Protection ability:

COB LED Screen has a layer of protective glue on the surface of the LED Panel, which can effectively prevent damage, static electricity, moisture, and surface cleaning; SMD LED screen lamp beads leak outside, so it is easy to knock off the lamp beads, and it is difficult to clean the surface, are also easily damaged by static electricity, which increases the failure rate and service life of the entire LED display.

Top Shine COB LED Screen Advantage

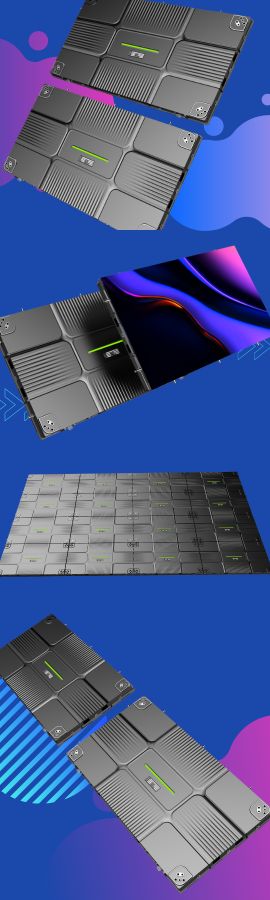

COB LED directly welds the RGB chip on the PCB and itself is very small. Therefore, in the same size, the resolution that the COB LED Screen can achieve will be higher. Extremely high pixel density enables high-definition display effects.

COB is currently the most advanced packaging technology, allowing the COB LED display to accurately reproduce various colors, making the picture more realistic and delicate.No graininess, more suitable for close viewing

COB LED Screen does not go through a secondary packaging process, reducing the viewing angle. Even if viewed from the side at 170 degrees, it can still maintain sufficient brightness and color.

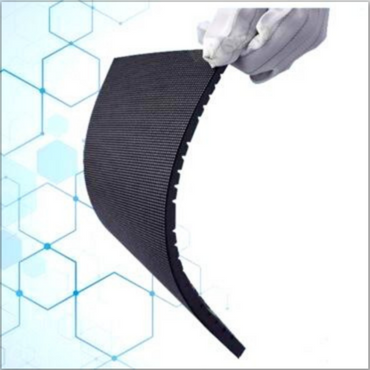

The COB LED pixels are encapsulated on the PCB board directly. The device is fully sealed and its surface is smooth and hard. It has a high level of protection, is dust-proof, waterproof, moisture-proof, anti-static. It also has strong pressure resistance.

The LED chip of the COB LED screen is directly welded on the PCB board, which can dissipate heat directly and quickly. The thermal resistance is low, so the COB LED display can always work at low temperatures, reducing the heat and power.

The full range of COB LED display cabinets adopt a box size of 600*337.5mm and a golden standard ratio, 16:9. The connectors adopt a hard-wired wireless design, making installation and disassembly very convenient.

- Advantages of COB LED Screen?

- COB LED Screen Datasheets

COB LED display is an LED display using COB packaging technology. Different from traditional SMD packaging technology, it integrates light-emitting chips into the PCB board instead of welding them to the PCB one by one. This COB packaging technology effectively improves the LED Issues such as the reliability, light color, and protective performance of the display screen providing a better visual experience.

Why are COB LED Displays so popular in the market?

This is mainly reflected in its display effect and performance advantages.

First, the COB display screen has the characteristics of anti-collision, waterproof and dustproof, and anti-static. Since the surface is cured with epoxy resin, the device is sealed on the PCB board and is not exposed, so even if it is bumped during transportation or shaken during installation, the light will not fall off or be damaged. At the same time, it can also effectively prevent damage to devices caused by moisture, dust, static electricity, etc. This greatly improves the stability and reliability of the display.

Secondly, the COB LED Video Walls has the characteristics of strong heat dissipation, low power consumption, and long life. Since the heat is quickly dissipated directly through the PCB board and the thermal resistance is small, the display can work at a lower temperature. This can reduce power consumption and heat generation and extend the life of the LED display. It is reported that the normal service life of the COB display can reach more than 80,000 hours. Thirdly, the COB display screen has the characteristics of smaller spacing, better image quality, and wider viewing angle.

Since there are no physical barriers between light-emitting chips, there are more display pixels per unit, so smaller pitches can be achieved (even below 0.9mm), clearer images (resolution up to 4K or above), and fuller displays (colors up to 16.7 M or above), the colors are more abundant (the color gamut can reach more than NTSC 100%), and the fineness is higher (the grayscale can reach more than 16 bit). At the same time, the “area light source” lighting method also effectively suppresses the moiré phenomenon and increases the viewing angle range (both horizontally and vertically up to 170°). These features make the display effect of the COB display even better.

Finally, the COB LED Video Walls has the characteristics of easier installation and more convenient maintenance. Since the COB LED display adopts an integrated module design, it eliminates the multiple processes and devices required for LED electronic screens using the SMD packaging process, which can save production steps and material costs. At the same time, it can also reduce the installation space and weight, and simplify the installation steps and methods. In addition, the COB display screen has high stability and reliability, so the failure rate is low and the maintenance cost is low.

| Cob led display | TC-0.78 | TC-0.93 | TC-1.25 | TC-1.56 |

| Pixel pitch(mm) | 0.78 | 0.93 | 1.25 | 1.562 |

| Pixel Density(dot/m2) | 1638400 | 1137777 | 640000 | 409600 |

| LED Type | COB | |||

| Module Size(W x H x D)mm | 150*168.75mm | |||

| Module resolution(W x H) | 192*216 | 160*180 | 120*135 | 96*108 |

| Module Weight(Kg) | 0.3kg | |||

| Power Consumption per Module(w) | 20 | 20 | 20 | 20 |

| Diver Mode(Scan) | 1/60 | 1/48 | ||

| Brightness(cd/m2) | 600CD | |||

| Grey Scale | 16 | |||

| Refresh Rate(Hz) | ≥3840Hz | |||

| Cabinet Size(W x H x D)mm | 600*337.5*39.5mm | |||

| Cabinet Weight(Kg/Cabinet) | 12.5KG | |||

| Max Power Consumption(W/m2) | 400W | |||

| Average Power Consumption(W/m2) | 120W | |||

| View Angle(H°/V°) | 160/160 | |||

| Mini View Distance(m) | 1 | |||

| Operating Use Temperature(℃) | -20℃~60℃ | |||

| Storage Use Temperature(℃) | -20℃~60℃ | |||

| Input Voltage(V) | 100~240V | |||

| Input Power Frequency(Hz) | 50Hz~60Hz | |||

| Failure Rate | <1/100,1000 | |||

| Signal Input Format | SDI, RGBHV,YUV,YC,Composite,HDMI,DVI,SD/HD-SDI etc. | |||

| Life Time(hrs) | 100,000 | |||

| IP Level(front/rear) | IP43 | |||

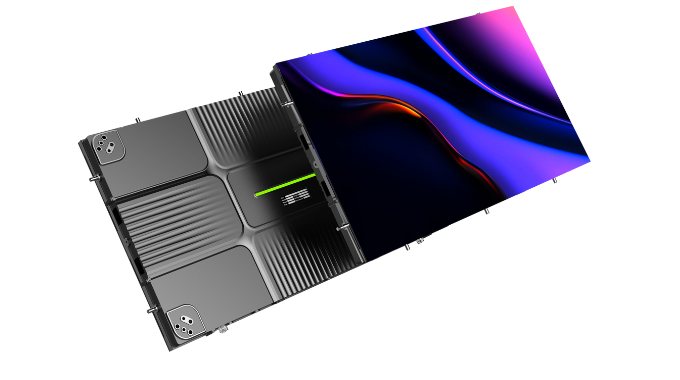

COB LED Screen Cabinet

Lightweight: only 4kg 1 cabinet

Ultra thin: only 29MM

High flatness

Quick installation

Related Product

One-Stop Solution for LED Display Board and System Needs.

COB LED Display market prospect and application analysis

COB LED Screen can easily achieve smaller spacing and stronger protection. COB packaging is to package the light-emitting chip directly on the PCB board, which is a completely real sealed device. No matter during transportation, installation, disassembly, etc. It is not afraid of the impact caused by collisions, and there will be no lights falling or breaking. During the later use of the COB LED Video Walls, the maintenance rate is extremely low and the service life is more guaranteed.

COB LED display screens are superior to SMD displays in terms of performance, image quality, lifespan, and cost, and have huge development potential and market prospects in the field of large indoor display screens. Some industry experts say that in the next few years, COB displays will occupy more than 80% of the global indoor display large-screen market.

At present, COB LED Video Walls have gradually been widely used in high-end conference rooms, exhibition halls, studios, center occasions, and other occasions, and are also being used in home theaters, commercial advertising, intelligent transportation, and other fields, gradually popularizing indoor displays. For large-screen applications, its development potential is unstoppable.

High pixel density: The COB LED screen has a high pixel density, which can provide clearer and more detailed images. Through the packaging of COB technology, multiple LED chips can be combined on one substrate to achieve higher pixel density, that is, more pixels per square inch (PPI) and a more delicate picture.

High brightness and high contrast: The LED lamp beads used in the COB LED screen have high brightness and can provide a very bright picture. At the same time, they have high contrast and can present clearer and more vivid images. Because COB LED screens can achieve higher pixel density, the picture is more uniform and graininess and color unevenness can be avoided.

Ultra-thin design: COB LED screens use COB packaging technology, which can package LED lamp beads in a very small space, thereby achieving an ultra-thin screen design. COB LED screens can also be customized and designed according to different use occasions to meet the needs of different places.

High stability and reliability: COB LED screen uses high-quality LED lamp beads and electronic components, which has high stability and reliability. COB LED screens have a long working life, are less prone to failure, and reduce maintenance and replacement costs.

Energy saving and environmental protection: COB LED screens use LED lamp beads as light sources. Compared with traditional display screens, they have lower power consumption and longer life. They are also more environmentally friendly, reducing energy waste and environmental pollution.